|

To avoid severe burns and equipment damage:

|

|

To avoid personal injury:

|

The ODS holds approximately half the volume of oil contained in a Velocity vat. To prevent splashing and spillage, drain no more than half of the oil in to the ODS at one time.

|

Burn Risk To avoid burns, use PPE when connecting to or disconnecting from oil disposal unit. |

|

To avoid personal injury, ensure cover is in place before moving shuttle. |

-

The shuttle works with multiple fryer models. Adjust the shuttle accordingly.

-

Release cover latch and hinge cover back on oil disposal shuttle. Make sure crumb catcher is in place.

-

Remove the filter pan assembly from under the fryer, and then roll the oil disposal shuttle under fryer until it stops. Make sure the fryer’s drain aligns with opening in shuttle.

-

Perform the drain procedures from the operation manual for your model of fryer.

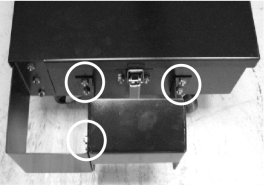

On LVE / LVG-10X fryers, if oil disposal shuttle is not properly in place, “IS DISPOSAL UNIT IN PLACE?” displays. Adjust center bracket on the front of shuttle as needed by loosening the 6 nuts holding bracket and moving the bracket up or down. Once properly adjusted, the control displays “DISPOSING”.

-

Remove the oil disposal shuttle from under the fryer and replace with the filter pan assembly.

-

Replace and latch the cover and roll oil disposal shuttle to disposal container.

-

Turn the thumb screw on the bracket to loosen pump assembly.

-

Swivel the pump assembly over the disposal container, and then tighten the thumb screw on the bracket.

-

Turn the pump handle rapidly (fast) in order to prime the pump and to get oil to flow through pump.

-

Once the shuttle is empty, loosen the thumb screw on the bracket, and swivel the pump assembly back over the lower unit and tighten the handle.

Follow the oil fill procedures from the operation manual for your model of fryer, and then return the fryer to normal operation.