Cleaning Dilution Box

|

Objects can fall and splash hot oil or hot water while performing this procedure. Cover the vat with a sheet pan or drain the vat and allow to cool otherwise serious burns may result. |

Cleaning the dilution box helps to ensure the unit operates efficiently and with few failures.

-

Ensure unit is off, and close and lock the lid.

-

Unscrew the wingnut on the lower left back access panel of the fryer, and remove access panel.

-

Clean the dilution box with a cloth, or brush.

-

Ensure the holes in the box are free of debris.

-

Replace back shroud when finished.

Depending on the breading location and conditions within the kitchen area, the dilution box may need cleaned more often.

- Spray biodegradable, food safe, foaming degreaser on Nylatrons.

- Raise lid up and down several times to spread the degreaser.

- Wipe Nylatrons to remove food soil, grease, and degreaser residue.

The lid rollers, in the back of the fryer, should be lubricated at least once a year, to allow the lid easy movement.

- Remove the back shroud of the fryer.

- Using spindle lube, part number 12124, place a small amount of lube on both top and bottom rollers. Ensure to lube both left and right rollers.

Inspect Counterweight Cables

|

NOTICE - |

If lid becomes difficult to operate, stop using the fryer and call for service. Cables need replaced. |

Henny Penny 8 Head fryers use two cables in the counter-weight mechanism that helps in the raising and lowering of the lid.

Cables should be visually inspected yearly, either as part of a planned maintenance program or during a routine service call. Cables more than 10 years old should be replaced regardless of inspection results.

- Using a 3/8” socket, remove the 6 keps nuts around the exterior of rear cover.

- Lift up on the rear cover and pull out at the bottom to clear threaded studs. (Removing top shroud makes it easier to remove the rear cover, but is not necessary.)

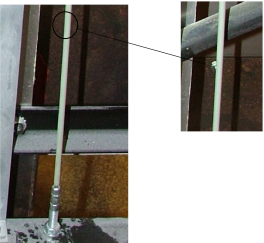

Counterweights with Cover Removed

- Inspect the counter-weight cables. If cables have cracks in the jacket, missing pieces in the jacket, or other obvious signs of wear, call for service to have both cables replaced.

Example of acceptable lid cable.