Filtering

The Henny Penny 590/592 Pressure Fryershould be cleaned and the oil must filtered and polished at least twice daily: after lunch rush and at the end of the day. Refer to KFC’s Standards Library. Filter oil immediately following a Cook Cycle when the oil temperature is in the “COOL” mode.

| Overflow Risk Only filter when "COOL" is displayed. Failure to do so can result in oil overflowing the vat, causing serious burns, personal injury, fire, and/or property damage. |

| To avoid severe burns when pouring hot oil into vat, wear personal protective equipment (PPE) and take care to avoid splashing. |

| To avoid personal injury, do not move fryer or filter pan while containing hot oil. The filter pan must be as far back under fryer as it will go, and the cover in place. Be sure the hole in the cover lines up with the drain before opening the drain. |

| Burn Risk To avoid severe burns, turn off filter pump and wear personal protective equipment (PPE) when touching union on filter tube. |

If there are air bubbles coming up in the oil, it’s possible that the filter connection at the union on the filter tube is not tightened properly. If so, turn off the pump and wear PPE when tightening the union.

| Burn Risk To avoid burns and damage to the filter pump motor, turn the diverter valve to the fill position when filter rinse hose is not in use. |

| Drain the oil at |

High volume cooking could cause the cold zone to fill quicker with cracklings and cleaning may be required more often. Part of the process involves removing cracklings from the cold zone of the vat.

Turn COOK/PUMP switch to OFF position.

Make sure filter pan is under fryer and the filter union is tightened to the standpipe, coming out of the pan.

Remove cooking racks and carrier, and wipe bottom of lid. Tilt lid out of the way to clean vat.

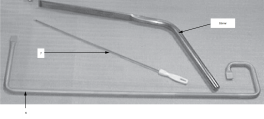

Use L-shaped brush to clean cracklings from the heating elements and from sides and bottom of vat as oil drains.

Use straight brush to push cracklings through drain opening in bottom of vat if necessary, and to clean between the heating elements and the vat wall.

When all of the oil has drained, scrape or brush the sides and bottom of the vat, and swing drain valve handle to the closed position.

If an optional filter rinse hose is available on your fryer, the following cleaning procedure may be used, otherwise continue onto step 9.

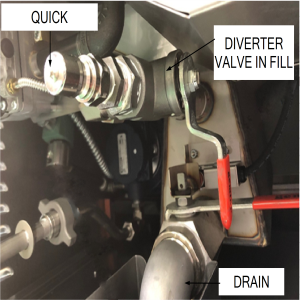

Attach the filter rinse hose with its quick disconnect fitting to the male fitting, located next to the filter valve handle. Slide back the spring ring on the female side of the quick disconnect fitting and let it snap into place over the male half of the fitting.

Turn the diverter valve to the filter rinse hose position.

With the end of the filter rinse hose aimed down into the fry vat, turn COOK/PUMP switch to pump.

Rinse the vat interior. Especially work on hard to clean areas, like the vat bottom and burner tubes.

After thorough rinsing with oil, turn the COOK/PUMP switch to OFF, close the drain valve and turn the diverter valve to the fill position.

Detach the hose and raise, the fitting end of hose, high for a minute to allow the remaining oil in the hose to drain into the vat.

Turn COOK/PUMP switch to PUMP.

When all oil has been pumped into vat, turn COOK/PUMP switch off.