Operating Components

| To avoid severe burns, do not open the drain valve while vat is under pressure. Allow the pressure to reduce to atmospheric pressure. |

| Burn Risk To avoid serious personal injury, do not obstruct discharge from the safety relief valve. During operation,this valve may discharge large amounts of high pressure steam, water, air, gas, or oil. |

| Burn Risk To avoid serious personal injury, keep body parts away from safety valve exhaust. |

| To avoid severe burns, do not tamper with safety relief valve while operating fryer. |

| To avoid serious personal injury, do not tamper with safety relief valve.Tampering with this valve will void agency approvals and appliance warranty. |

| To avoid personal injury:

|

| Shock Hazard Access covers for fryers with Pressure Assist are connected with electrical wiring to the control. To avoid electrical shock, a service technician must perform any activities related to the USB port. |

| Do not use the test lever or ring as a lifting device for installation. |

POWER/PUMP Switch | A three way switch with center OFF position; move the switch to the position marked POWER to operate the fryer; move the switch to the position marked PUMP to operate the filter pump; certain conditions must be met prior to operation of the filter pump; these conditions are covered later in this section. |

Vat | This reservoir holds the cooking oil, and is designed to accommodate the heat exchanger, 8 head of product and an adequate cold zone for collection of cracklings |

Carrier | This stainless steel carrier consists of five racks which contain the food product during and after frying |

Drain Valve | A two-way ball valve, normally in the closed position; turn the handle to drain the oil from the vat into the filter pan |

Drain Interlock Switch | A microswitch that provides protection for the vat in the event an operator inadvertently drains the oil from the vat while the main switch is in the POWER position; the switch is designed to automatically shut off the heat when the drain valve is opened |

Oil Mixing System | A oil mixing capability to help ensure oil is properly mixed to prevent an accumulation of moisture and hence boiling action in the vat; the filter pump is activated by the controls, at preset intervals, to mix the oil |

Lid Gasket | Provides the pressure seal for the vat chamber. |

Lid Latch | The fryer lid is equipped with a mechanical catch on the front of the lid which engages a bracket on the front of the vat; this device holds the lid down while the lid is being locked into place, but is not meant to hold pressure in the vat. |

Air Valve | Pumps air into the oil, periodically, to keep the oil at a uniform temperature; this only functions when the unit has been sitting idle for a period of time, and when heating up from a cold start. |

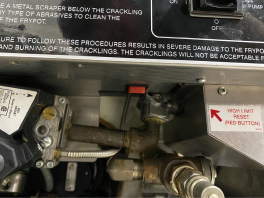

High Limit

| This high temperature control senses the temperature of oil; if the temperature of the oil exceeds 450°F (230°C), this control will open and shut off the heat to the vat; when the temperature of the oil drops to a safe operation limit, the control must be manually reset by pressing the red reset button, located under the control panel, in the right, front of the fryer. A control that senses the temperature of the oil; if the temperature of the oil exceeds the safe operating limit, this control opens and shuts off the heat to the fryer; when the temperature of the oil drops to a safe operation limit, the control must be manually reset by pressing the red rocker switch for 5 seconds. The red rocker switch is located under the control panel.

|

|---|---|

Filter Pan | The removable pan that houses the filter and catches the oil when it is drained from the vat; also used to remove and discard old oil. |

Filter Union | Connects the filter to the filter pump, and allows easy removal of the filter and filter pan |

Fuses | A protective device which breaks the circuit when the current exceeds the rated value |

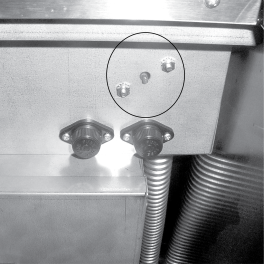

USB Port | C8000 ARM control’s USB port is located inside an access cover on the back of the control. Remove the control panel screws and lower the control panel to the service position. When inserting a flash drive, the label or logo should face away from you. |

| Deadweight Assembly | The deadweight style operating pressure relief valve is used to maintain a constant level of steam pressure within the vat; any excess steam pressure is vented through the exhaust stack; remove the deadweight cap, and clean the cap, weight, and deadweight orifice once a day. |

| Safety Relief Valve | An ASME approved spring loaded valve set at 14.5 psi (999 mbar); in the event the operation valve becomes obstructed, this safety valve releases excess pressure, keeping the vat chamber at 14.5 psi (999 mbar); if this occurs, turn the COOK/ PUMP switch to the OFF position to release all pressure from the vat. |

| Pressure Gauge | Indicates the pressure inside the vat. |

Solenoid Valve | An electromechanical device that causes pressure to be held in the vat. The solenoid valve closes at the beginning of the Cook Cycle and opens automatically at the end of the Cook Cycle; if this valve becomes dirty or the teflon seat nicked, pressure will not build and it must be repaired per the Maintenance Section of the Technical Manual. |

Condensation drain pan | The collection point for the condensation formed within the steam exhaust system; it must be removed and emptied periodically, usually daily. |

Ignition Modules | The two ignition modules send 24 volts to the gas control valve and high voltage to the ignitors |

Spark Ignitors | When the pilots are being lit, the spark ignitors are electrically energized and the tip of the ignitors spark to ignite the pilot lights |

Flame Sensors | Sense the pilot lights when the power switch is turned on; if the pilots go out, or do not light, the flame sensors shut the gas off, via the modules |

Gas Control Valve | A dual controller, in which, one side of the valve controls the pilot light and the other side controls the main burner |

Airflow Switch | Senses the flow of air coming from the blower; if the airflow is reduced below a set amount, the switch cuts power to the gas control valve, which shuts down the burners |

Blower | Adds the proper amount of air into the burner tubes, so an efficient combustion takes place, and also, pulls the flue gases out to the flue |

Air Valve | Pumps air into the oil, periodically, to keep the oil at a uniform temperature; this only functions when the unit has been sitting idle for a period of time, and when heating up from a cold start. |