Installing

Due to the variations of equipment installations from one store to another, we are providing only a general process which the installer can use for reference or as a checklist. All electrical, water, and drain connections must comply with all federal, state, county, and local codes.

|

Shock Hazard To avoid property damage, do not puncture unit with tools during unpacking. |

|

NOTICE - |

ALL units MUST have a water supply connection and a plumbed drain. |

|

NOTICE - |

When locating, moving, or positioning the holding cabinet, be careful not to scratch the table surface. |

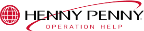

AHC-990

- Position cabinet so controls are accessible.

-

Locate the cold water fill line and drain is under the unit.

-

Layout routing of 1/4 inch fill line from the holding cabinet male quick disconnect under the unit to a cold water source. (Both male & female disconnects are supplied with the units)

-

Using an 1/8” to 1/4” reducer, a 1/4” x 6 ft. coiled hose (see below) can be attached to the female disconnect and the coiled hose is then connected to the in-coming water line.

-

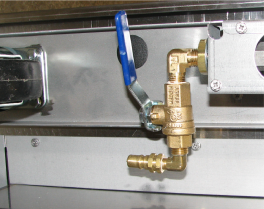

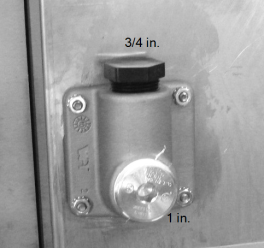

Layout routing of drain line from a 3/4” side outlet or 1” bottom outlet in drain block under unit to an open drain.

-

Several options are available for the AHC-990 drains:

-

Install cabinet over floor drain for nightly draining.

-

Disconnect water line and roll cabinet to nearest floor drain for nightly draining.

-

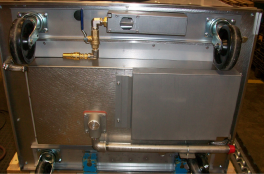

Use the Henny Penny drain kit, part no. 03697 for nightly draining. See photo at left.

-

-

Connect water line to holding cabinet.

-

Connect electrical power to unit.

-

Be sure fill tray angles down so water flows freely into pan.

-

Check cabinet for proper operation and repair any water leaks.

|

NOTICE - |

If necessary, the shut-off valve under the unit can be used to help regulate the water flow into the water pan. Normally, these should be opened fully. |

AHC-993

-

Position cabinet so controls face the store’s drive-thru area.

-

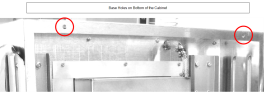

Remove 2 screws and bottom panel at front of unit.

-

Remove 2 screws and bottom panel at rear of unit.

-

Measure and center unit front to rear on the table top with one side flush with the table end.

-

Using the holes in the cabinet base as guides, mark 4 mounting hole locations in the table top.

-

Layout routing of 1/4 inch fill line from the holding cabinet male quick disconnect under the unit to a cold water source.

-

Layout routing of drain line from a 3/4” side outlet or 1” bottom outlet in drain block under unit to an open drain.

-

Layout routing of electrical power cord from the top of the cabinet to the proper receptacle.

-

Measure, mark, and drill or cut holes or other openings in table top and/or shelves as dictated by this specific installation to permit routing of water, drain, and electrical lines.

-

Fabricate the planned drain line.

-

Move unit to expose two marks at the front, center punch each mark, and drill 3/16” pilot holes.

-

Drill final holes using a 5/16” bit. Clean up all debris and metal shavings.

-

Position unit so the holes in the table top align with the mounting holes in the base.

-

Install four 1/4” stainless steel screws and flat washers from underneath table and install four stainless steel flat washers and lock nuts on screws from above the base lip.

-

993’s should have about 10” of clearance between them to accommodate the packaging shelving tower (see below).

-

Perform a final positioning of the cabinet with one side flush with the table end and centered front to back on the table top.

- Tighten the fours bolts and nuts securely.

-

Apply a bead of clear silicone sealer around cabinet base to fill gaps between table top and base.

-

Connect water line and drain line to holding cabinet.

-

Connect electrical power to unit.

-

Enure fill tray angles down so water flows freely into pan.

-

Check cabinet for proper operation and repair any water leaks.

-

Install bottom panel at front of unit with 2 screws.

- Install bottom panel at rear of unit with 2 screws.

|

NOTICE - |

If necessary, the shut-off valve under the unit can be used to help regulate the water flow into the water pan. Normally, these should be opened fully. |