Error Codes

In the event of a control system failure, the digital an error message displays. The message codes are shown in the DISPLAY column below. A constant tone is heard when an error code displays, and to silence this tone, press any button.

|

Display |

Cause |

Correction |

|---|---|---|

|

“E-4” |

Control board overheating. |

Turn switch to OFF position, then turn switch back to ON; if “E-4” displays, the control board is getting too hot; check the louvers on each side of the unit for obstruction. |

|

“E-5” |

Oil overheating. |

Turn switch to OFF position, then back to ON; if “E-5” displays, the heating circuits and temperature probe should be checked. |

|

“E-6A” |

Temperature probe open. |

Turn switch to OFF position, then back to ON; if “E-6” displays, the temperature probe should be checked.

|

|

“E-6B” |

Temperature probe shorted. |

|

|

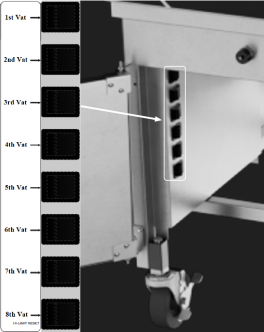

“E-10” "E-10 A" "E-10 B" "E-10 C" "E-10 D" "E-10 F" "E-10 M" "E-10 Y" |

High limit High limit tripped above 300° F High limit tripped below 300° F High limit tripped while cooking High limit tripped less than 5 minutes of Auto Filter High limit tripped during filter cycle High limit tripped during melt mode High limit tripped less than 5 minutes of "YES" |

Let the unit cool down (15-20 minutes), reset the high limit by pressing and holding the appropriate high limit reset switch for 5 seconds. If high limit does not reset, contact service provider. (Vat 1 refers to the far-left vat.) For single well units, open door and the reset switch is located up and underneath.

|

|

“E-15” |

Drain switch. |

Ensure drain knob is completely pushed-in; if E-15 per- sists, have drain switch checked. |

|

“E-18A” |

Left level sensor open. |

Turn switch to OFF position, then back to ON; if display still indicates a failed sensor, have the connections checked on the control board. Have sensor check and replaced if necessary.

|

|

“E-18B” |

Right level sensor open. |

|

|

“E-18C” |

Both level sensors open. |

|

|

“E-21” |

Slow heat recovery. |

Have a certified service technician check the fryer for cor- rect voltage to the unit; have heat circuit checked; have unit checked for loose or burnt wires. |

|

“E-22” ”NO HEAT” ”CHECK PWR CORD AND BREAKER” |

Elements not heating. |

Have power cord and heat circuit checked. |

| "E-31" | Elements are up | Lower elements completely into vat. |

|

“E-41” ”E-46” |

Programming failure. |

Turn power switch to OFF, then back to ON; if an error code displays, have the controls re-initialized; if error code persists, have the control board replaced. |

|

“E-47” |

Analog converter chip or 12-volt supply failure. |

Turn power switch OFF, then back to ON; if “E-47” per- sists, have the I/O board, or the PC board replaced; if speaker tones are quiet, probably I/O board failure; have the I/O board replaced. |

|

“E-48” |

Input system error. |

Have PC board replaced. |

|

“E-54C” |

Temperature input error. |

Turn power switch to OFF, then back to ON; have control PC board replaced if “E-54C” persists. |

|

“E-60” “FILTER IN USE” |

AIF PC board not communicating with PC board. |

Turn power switch to OFF, wait 15 seconds, then turn switch back to ON. If “E-60 persists, have connector be- tween the PC boards checked; replace AIF PC board or control PC board if necessary. |

|

“E-60” “FILTER IN USE” |

AIF PC board not communicating with PC board. |

Turn power switch to OFF, wait 15 seconds, then turn switch back to ON. If “E-60 persists, have connector be- tween the PC boards checked; replace AIF PC board or control PC board if necessary. |

|

“E-70C” |

Drain valve jumper wire missing or disconnected. |

Have the jumper wire checked on the PC board at drain switch interlock position. |

|

“E-93” ”24 VDC SUPPLY TRIPPED” |

Autolift motor malfunction or failure. |

If AutoLift feature is not operating, have each of the Auto- lift motors checked. Check the 24V circuits. |