Electrical Requirements

|

Ensure the operator can verify that the electrical plug is removed from power, from all access points around the fryer, to prevent personal injury when maintaining the fryer. |

|

Shock Hazard

|

|

(FOR EQUIPMENT WITH CE MARK ONLY!) To prevent electric shock hazard this appliance must be bonded to other appliances or touchable metal surfaces in close proximity to this appliance with an equipotential bonding conductor. This appliance is equipped with an equipotential lug for this purpose. The equipotential lug is marked with the following symbol. Equipotential Ground Symbol = |

|

To avoid electrical shock or property damage, disconnect power before installing or servicing equipment.A qualified technician must perform the installation. |

Cable Restraint

Secure I-bolt to building using acceptable building construction practices.

Permanently connected electric fryers with casters must be installed with flexible conduit and a cable restraint, when installed in the United States and internationally. Holes are available in the rear fryer frame for securing the cable restraint to the fryer. The cable restraint does not prevent the fryer from tipping.

CE units require a minimum wire size of 6 mm to be wired to the terminal block. If a flexible power cord is used, it must be HO7RN type.

|

NOTICE - |

It is recommended that a 30 mA rated protective device such as a residual current circuit breaker (RCCB), or ground fault circuit interrupter (GFCI), be used on the circuit.

|

Units being used outside the United States may not be shipped with the power cord attached to the unit because of the different wiring codes. The fryers are available from the factory wired for 200, 240, 380 and 415 volts, 3 phase, 50 Hertz service. A terminal block is mounted inside the fryer for the cable wiring.

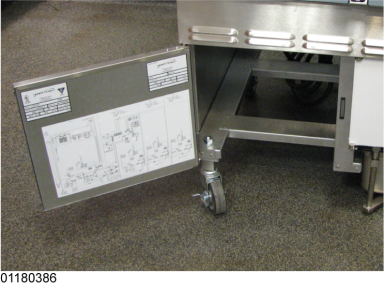

Check the data plate mounted on the inside of the left door to determine electrical requirements for the fryer, see Figure 2-4 Data Plate Location, page 9. Refer to local electrical codes for correct grounding (earthing) procedures or in absence of local codes refer to the National Electrical Code ANSI/NFPA No. 70 (the current edition). Each vat has its own power cord assembly. An all pole separate disconnect switch with proper capacity fuses or breakers must be installed at a convenient location between the fryer and the power source. The disconnect switch must be installed according to national and local codes. It should be an insulated copper conductor rated for 600 volts and 90° C. For runs longer than 50 feet (15.24 m) use the next larger wire size. CE units require a minimum wire size of 6 mm to be wired to the terminal block. It is recommended that a 30 mA rated protective device such as a residual current circuit breaker (RCCB) or ground fault circuit interrupter (GFCI) be used on the fryer circuit. Electrical requirements for each fryer are found on the inside of the left door.

| Volts | Phase | Hertz | kW per vat | Amps per vat | Wire |

| 220/380 | 3 | 50/60 | 14.0 | 24.3** | 3NG |

| 230/400 | 3 | 50/60 | 14.0 | 24.3** | 3NG |

| 240/415 | 3 | 50/60 | 14.0 | 24.3** | 3NG |

** Split vats include two 7.0 kW heating elements connected to one power cord.

**Additional amperage required to operate Laboratory certifications non-heating electrical components. † Units shipped without power cord and plug must have power cord and plug installed on site by a qualified electrician.

|

Heat System |

Hood Interlock |

|---|---|

|

208, 240 V only |

5-wire only |

|

|

|

|

3NG NEMA 15-60P |

NEMA L21-20P |

Straight plug only.

Plug configurations will vary according to destination.