Troubleshooting

|

Problem |

Cause |

Correction |

|---|---|---|

|

Power switch on but fryer completely inoperative |

Open circuit |

Fryer plugged in Check breaker or fuse at wall |

| Pressure not exhausting at end of Cook Cycle | Solenoid or exhaust line clogged | Turn OFF and allow fryer to cool to release the pressure in vat; have all lines, solenoid, and exhaust tank cleaned |

| Operating pressure too high | Deadweight clogged |

Turn OFF and allow fryer to cool to release the pressure in vat; clean deadweight; see Cleaning the Deadweight Assembly |

| Operating pressure too high | Deadweight clogged |

Turn OFF and allow fryer to cool to release the pressure in vat; clean deadweight; see Cleaning the Deadweight Assembly |

| Operating pressure too high | Deadweight clogged |

Turn OFF and allow fryer to cool to release the pressure in vat; clean deadweight; see Cleaning the Deadweight Assembly |

| Operating pressure too high | Deadweight clogged |

Turn OFF and allow fryer to cool to release the pressure in vat; clean deadweight; see Cleaning the Deadweight Assembly |

| Operating pressure too high |

Deadweight clogged Exhaust line to stack clogged. |

Turn OFF and allow fryer to cool to release the pressure in vat; clean deadweight; see Cleaning the Deadweight Assembly Clean exhaust line to stack. |

| Pressure does not build |

Not enough product in vat Metal shipping spacer not removed from deadweight assembly. Pressure not programmed Lid gasket leaking |

Place full capacity product in vat when using fresh oil Remove shipping spacer; see Unpacking Check programming Reverse or replace lid gasket |

| Pressure does not build |

Not enough product in vat Metal shipping spacer not removed from deadweight assembly. Pressure not programmed Lid gasket leaking |

Place full capacity product in vat when using fresh oil Remove shipping spacer; see Unpacking Check programming Reverse or replace lid gasket |

| Pressure does not build |

Not enough product in vat Metal shipping spacer not removed from deadweight assembly. Pressure not programmed Lid gasket leaking |

Place full capacity product in vat when using fresh oil Remove shipping spacer; see Unpacking Check programming Reverse or replace lid gasket |

| Pressure does not build |

Not enough product in vat Metal shipping spacer not removed from deadweight assembly. Pressure not programmed Lid gasket leaking |

Place full capacity product in vat when using fresh oil Remove shipping spacer; see Unpacking Check programming Reverse or replace lid gasket |

| Pressure does not build |

Not enough product in vat Metal shipping spacer not removed from deadweight assembly. Lid open or not latched Deadweight valve leaking. Pressure not programmed Lid gasket leaking |

Place full capacity product in vat when using fresh oil Remove shipping spacer; see Unpacking Close and latch lid Follow instructions in Cleaning the Deadweight Valve Check programming Reverse or replace lid gasket |

| Oil overheating |

Check oil temperature Check if contactor is working Faulty PC Board Faulty probe |

Check temperature in Programming Mode Check contactor and replace if necessary Remove and replace control panel Follow instructions in Replacing the Temperature Probe |

|

Oil not heating |

Gas valve knob turned to the OFF position Drain valve open High temperature limit tripped Blown fuse or tripped circuit breaker at supply box or control panel Blown fuse at control panel Faulty cord and plug Faulty contactor Faulty power switch Faulty drain switch Faulty PC board

|

Make sure gas control valve knob is turned to the ON position Close drain valve Reset high temperature limit Reset breaker or replace fuse Check and replace fuse Check cord, plug, and power at wall Check contactor and replace if necessary Check power switch and replace if necessary Check drain switch and replace if necessary Remove and replace control panel |

|

Foaming or boiling over |

See Boil-Over chart on fryer Water in oil Condensation line clogged Cold zone full of cracklings Cleaning solution in oil |

Follow boil-over procedures from chart At end of cooking cycle, drain oil and clean vat. Add new oil. Remove and clean condensation line. Filter oil Clean and neutralize the vat. Rinse with vinegar to remove the alkaline, then rinse with hot water and dry vat. |

|

Oil not draining |

Drain valve clogged |

Push cleaning rod through open drain valve. |

|

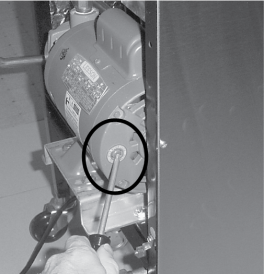

Filter motor won’t run |

Motor overheated |

Reset motor; see Filter Motor Protector Manual Reset Section |

| Oil leaking from drain valve |

Obstruction in drain Faulty drain valve |

Remove obstruction Follow instructions in Replacing the Drain Valve |

| Lid won't move up or down |

Cable on counterweight loose or broken. Check operation of counterweight carriage |

Replace or adjust counterweight cable per Replacing the Lid Counterweight Cables Adjust counterweight carriage |

|

Product Color Not Correct: A. Too Dark |

Temperature too high Breading too far in advance Overshooting the setpoint temperature |

Check temperature setting in the Program Mode Bread product closer to frying period Adjust PC Factor (may require a service call) |

|

B. Too Light |

Temperature too low Fryer incorrect preheat Wrong product button pressed |

Check temperature setting in the Program Mode Allow proper preheat time Be sure to press the correct product to be cooked |

|

C. Product Greasy |

Oil old Temperature too low Vat overloaded Product not removed from vat immediately after end of cycle |

Replace oil Check temperature setting in the Program Mode Reduce cooking load Remove product form vat promptly |

The filter pump motor is equipped with a manual reset button, located on the